Soft Matter Hacker Talks |

|

|---|

Home - Research - Publications - Blog - Talks - About

Twitter | Instagram | LinkedIn | Google Scholar | Scopus | ResearchGate | UNSW | YouTube

Thanks to Akshat and Andrew for the kind invitation to speak at your workshop. I'm really happy to attend and hear from all of the assembled minds about the future for us and for our students in the enduring space of chemical engineering design. Like all of you, many of my efforts in teaching design stem from direct interactions with industry and the diverse challenges they face every day. My motivation for the course I developed and will discuss today came from one of these interactions.

I asked an industry colleague about their suggestions to better train students to be "job-ready". Like many of these conversations, at first it was hard to go beyond generalities like "shorten the on-boarding time" and "more relevant case studies" as a way to better train students. As we dug deeper, something came up that stuck with me. They mentioned that the students that stand out for them bring skills that supplement the employers' existing skill base. We termed this "Job-enriching", where students bring NEW skills to the employer, rather than "Job-ready" where they come ready to be taught company-specific skills and existing culture.

So, this formed the nucleus of an idea and a goal for me: Could I create a course that would give students something to discuss during their interviews that would be new to the employer?, Something they had not heard before?, Something that would be immediately relevant and beneficial to their future work at the company? Building on this, I wanted to really think about what we could impart and teach students that they SHOULD learn from a company but often don't, like risk-taking and innovation. And I decided the best place to do that was in the Product Design context.

This course of study is not meant to be exclusive of traditional Chemical Engineering, as it also fills gaps for engineers headed to different industries than commodity chemicals and petroleum processing. Companies can struggle to get these engineers up to speed in the reality of working with highly non-Newtonian fluids like polymer melts, and dealing with complex fluids where small amounts of additives radically change rheology and flow. In these industries, for example, mixing often surpasses reaction engineering in complexity, as it is rare to be able to use turbulence to speed mixing. Students then need to understand new equipment, like static mixers, as well as positive displacement pumps and their distinct design requirements.

So why teach chemical engineers product design? Well, one really good reason is to enable them to develop value-added solutions that contribute to global finance, health, and equity. While examples abound of chemicals that deliver enormous value and profit margin, like pharmaceutical actives, it is easy to argue that the creation of stable, viable, and scalable products using those chemicals is at least or more valuable.

We teach that the uniqueness of chemical product development is distinct from historical chemical process development. Where the latter centers on system composition, optimizing chemical purity, the former is centered on the idea that the same composition can be combined in a different order of addition, or processed differently, and produce an entirely different material because of variations in structure. Mayonnaise is an everyday example, and the experience making it ranges from traumatic for unsuccessful attempts, to sublime for the more experienced. Key is the idea that the combination of materials is not enough, you need to understand the physicochemical factors that allow it to successfully form structure, flow, respond, and be stable.

A more modern recent example is the COVID vaccine, where the creation of the mRNA material was not accessible at scale until a stable lipid nanoparticle formulation could be developed AND produced at scale via impinging jet technology. This latter concept, developed by Bob Prud'homme and his group at Princeton, has made enormous contributions to global health and product viability by taking a chemical engineering approach to properly balance the extensional mixing time scale of impinging jets and the time scale of stabilization of nanoparticles as they form. And none of these required chemical reactions.

So why was I so sure that chemical engineers could integrate product design? I know because I lived it. Chemical engineers can make products as well as processes. I spent 15 years with the Procter & Gamble Company in the US working in their central engineering labs to support all of their Global Business Units. Our groups provided design and troubleshooting in key areas like fluid mixing, rheology, microstructure, and granular materials. For years we enabled process development and scale-up, but over time recognized the equivalent expertise was applicable to product design and development.

The Chemical Product Design Project Thesis is the capstone course of our new Chemical Product Engineering stream at UNSW. The degree provides a complement to the traditional chemical process engineering stream by adding some chemistry, removing Process Design Project, and requiring students take CEIC6711, Complex Fluid Microstructure and Rheology. This course lays the foundation for understanding key aspects of colloid, surfactant, and polymer science (and their biological analogues) as a way of designing valuable fluid microstructures. Many industries use complex fluid microstructures to make liquid products with stability, value, and manufacturability.

So I teach Chemical Product Design at UNSW as a group-based work that satisfies the requirements for an Honours Thesis. The course is designed to immerse the students in a fictitious company where they vie to develop new products within a theme I define each year. The theme is broad but sufficiently constrained that it is easy to tell if they meet the principle, allowing multiple innovations, but keeps them from spiralling off into all possibilities. Thesis A has a 2 hour lecture and a 1.5 hour workshop each week. The lecture teaches the principles of consumer needs, tech push and pull, underserved markets and segments, the selection of ideas by economic, technical, and scale-up feasibility. The workshop digs into product case studies and has the students practice pitching and digging into the market and the technology with immediate peer and instructor feedback. They then go through several stages where they must pitch a preliminary concept and then a more mature one later to their peers and to industry mentors. Instead of a Literature Review for Thesis A, the students write an Intellectual Property strategy document to outline their invention, its business benefits, and the proposed IP approach, either patenting, trade secrets, or others.

The second semester, Thesis B is unique in that its output is a full working product prototype as well as a draft patent or trade secret document. This requires the students work several hours each week in the lab to make, test, and optimize their products. At the end of the semester the products are demonstrated to an industry and alumni audience in a trade show format poster session.

We initially work out of Cussler and Moggridge as a basis for developing their product ideas, using their framework of identifying Needs, conceiving Ideas, Selecting the best of those ideas, and Manufacturing or Making the product. Here students consider Needs that are driven by Economic, Regulatory, Health, Trends, and Technological (can be pull or push) forces. They also consider the importance of equity, recognizing underserved communities and representation. They develop Ideas via classic brainstorming and workshopping sessions where they record them all, then classify. Here we emphasize the importance of adapting ideas, combining ideas, and the power of analogies to see things differently. During Selection students consider elements of feasibility from a technical, economic, and speed perspective. Manufacture is a key element. While our primary focus is product development, a core element of idea selection is technical but then also scale-up feasibility. Transformation of raw materials into product is the framework here, answering how a product prototype could be handed off to manufacturing personnel and enable rapid production.

We emphasize the importance of students drawing on their experience, culture, and community to create products that serve people who are traditionally underserved. The case studies we teach draw on commercially successful examples like Tristan Walker's company, Bevel, that created a shave care system providing African-American men with a product that did what all razors available at the time couldn't: give a close shave without causing razor bumps.

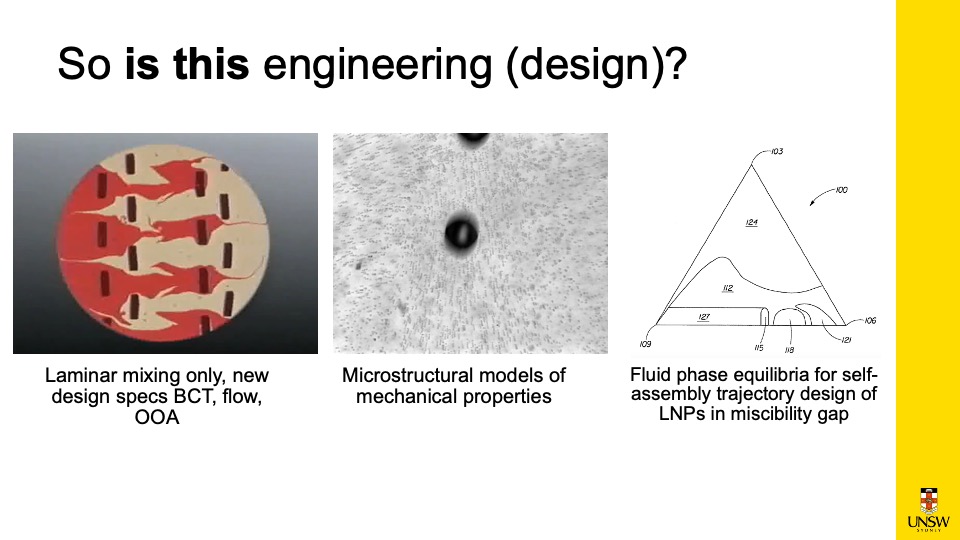

One point of concern for people is often whether the course uses the student's chemical engineering fundamentals in the course of the project. We do, in several ways. Analyzing competitive or inspirational products requires significant reverse-engineering. It is also critical to assess the technical feasibility of the product as it continues to evolve. Can we do it with less material or less-pure components? Examples include the ternary phase diagram of common oil-water-surfactant systems for liquid products. These allow optimization for minimal material usage and consistent properties like surface tension, rheology, and active ingredient levels/state. Other examples include benchmarking mass transport in systems with complex flow properties and varying characteristic length scales as well as quantifying complex fluid microstructures. Fluid mixing without turbulence is a good extension of classical fluid mechanics teaching, as is the design of systems to suspend different dispersed species using yield stress concepts rather than viscosity.

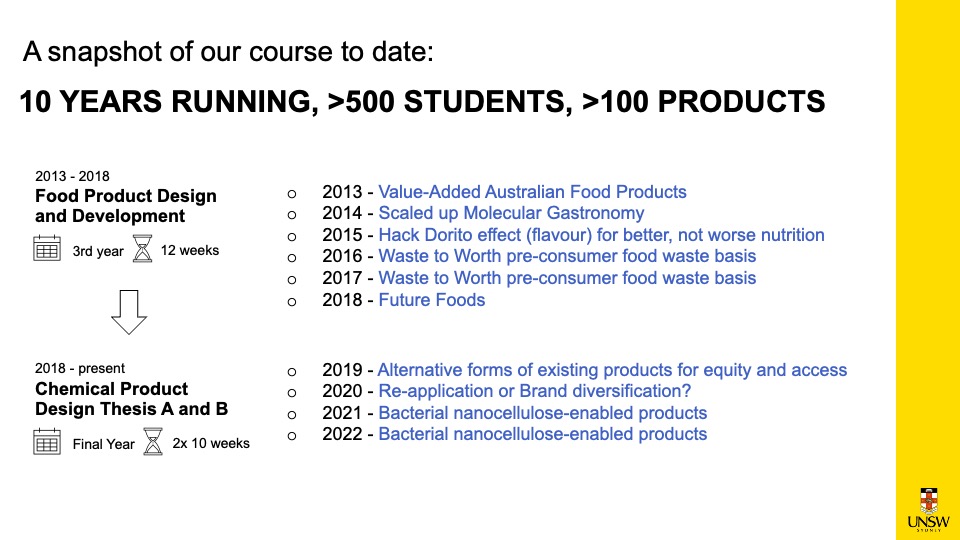

This course originated from a Food Science course I taught for 6 years. A single semester, 12 week capstone course that required teams to conceive of a novel product idea around an assigned theme, pitch it, and develop it in parallel in a lab, then present a prototype at the end of the semester.

When I decided to develop the Chemical Product Design project, UNSW was transitioning to trimesters, so we expanded from one 12 week semester to two 10 week trimesters. I based it on the structure of an Honours Thesis with Thesis A transforming from a Literature Review into an IP Strategy document and Thesis B becoming the experimental development of a prototype in the lab while documenting background, competition, formulation examples, and performance benchmarks in a patent or trade secret document. I had to propose and defend the courses before our Faculty Curriculum Committee and was asked how I was so sure the students could complete such an ambitious thing, developing a new-to-the-world product in only 20 weeks, and I was able to reply that they had previously done it in 12 weeks, without any failures to deliver, in 6 years.

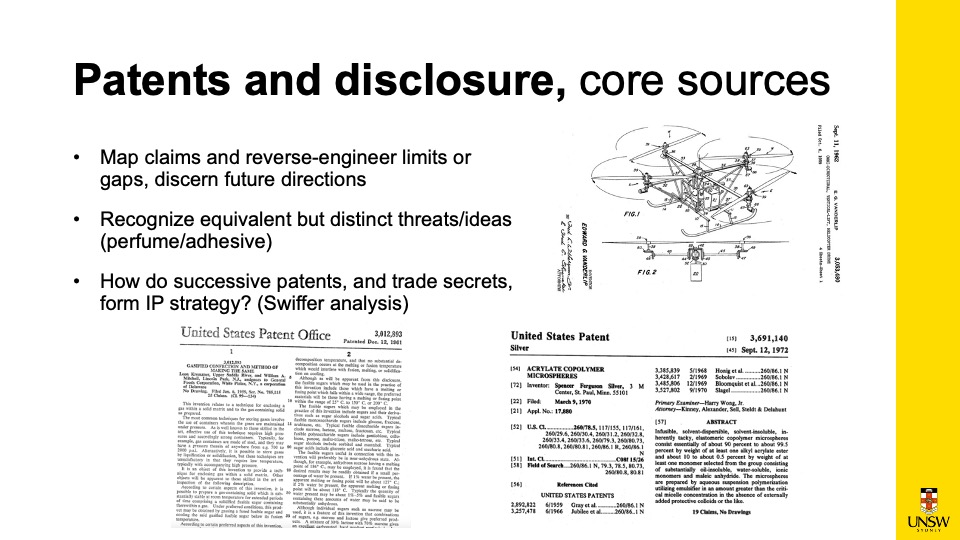

A lot of examples and discussions center around Intellectual Property, IP. Students learn the embodiment of an idea can be limiting, and practice reducing the description of a product and its functions to its base concepts. This often leads to realizing you have competition or blocking IP from completely different sectors. But it also enables the reverse, adapting surprising existing technology to innovate in a new area. A case study that is particularly illuminating is how Procter & Gamble needed to create perfume-containing capsules that release during daily wear of clothes. This means defining them as polymer shells with a failure modulus at intermediate stresses while holding organic cargo, which turned out to be quite similar to the capsules used in pressure-sensitive adhesive technology by Avery Dennison, enabling a rapid development alliance.

Analysis of patents is used to enhance student's ability to connect claims and ideas to potential and existing products. One example is the pop rocks patent - ask someone to describe Pop Rocks and they will say it is a candy that bubbles in your mouth when you eat it. The patent discloses a method of encapsulating gas with carbohydrates at high pressure using their glass-forming properties. The students then immediately do an exercise where they try to "work around" the patent, looking for gaps in the claims that would allow an alternative product to be developed. The deconstruction of the product concept in the patent language of something formerly familiar shows them the elements they can examine. They quickly suggest using gas other than CO2, using different means to impart pressure, or altering the materials to exploit new or combined ingredients not disclosed in the original.

Other examples are the patent for Post-It notes, showing the development there is actually a weak adhesive, not a square of paper. We also examine patents like the original drone patent, that was created in the early 60s but only became a broadly viable product with modern GPS and phone technology.

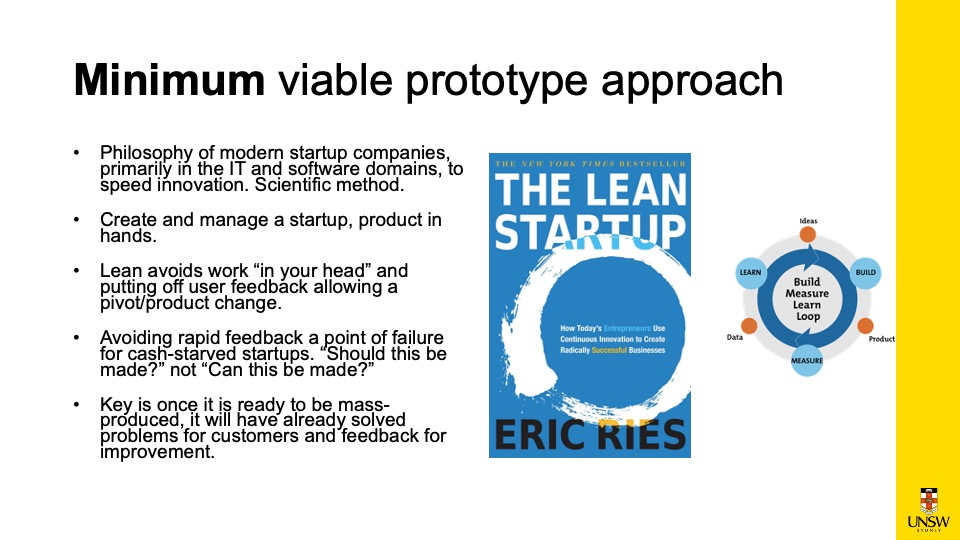

This course is really focused on creating a working product prototype as early as possible. We teach from Lean Startup practice the concept of a Minimally Viable Prototype. This means getting something that can be shown to consumers and customers and enable early feedback. This avoids working on a purely theoretical or paper-based product without testing its viability and enabling improvement.

Over time we noticed students took safe approaches to the assignment that were excessively risk-averse. As part of the product vetting process I push for ambitious and surprising approaches so that students can set their ideas apart from the field. Over time I realized that the idea of intelligent risk-taking needed to be taught explicitly and Christensen's Innovator's Dilemma is the framework used. I also ensure that the students see the difference between the more conservative mentor feedback they get from conventional experienced product developers and highly optimistic ambitious suggestions I typically make. You need both in a company culture, and they have to listen to one another, but the students need to see that companies WANT risk-taking but can sometimes build cultures that DISCOURAGE risk-taking. We use the Innovator's Dilemma examples to show why risk is so important to avoid being surpassed by upstart innovators who transform a premium product into something affordable in a short cycle. We also teach why it is hard to sustain risk-taking in a company and how they can keep it alive by aligning with supportive management and learning how to communicate the value of their innovations and the ACTUAL degree of risk being proposed.

I try to check whether this teaching gets results, and one cool outcome proved to me that the students do learn to embrace intelligent risk-taking. Benchmarking over the years, I can accurately predict now when in the semester (typically 60% through the second semester) when 10-15% of the students will pivot or change their product idea because they see a chance to enhance its impact. Being willing to sometimes radically pivot their project direction is a real risk, but it's important that they make that objective decision if it's for the best. This creates extra work for them, given all the documentation required, but they are motivated by the potential benefits. An example is the pepper extinguisher project that initially targeted an enzymatic active material that required careful stabilization and had variable performance depending on formulation. They acted as their own upstart competitor and benchmarked against a simpler more common active used in toothpaste that worked as well but was more consistent and much cheaper.

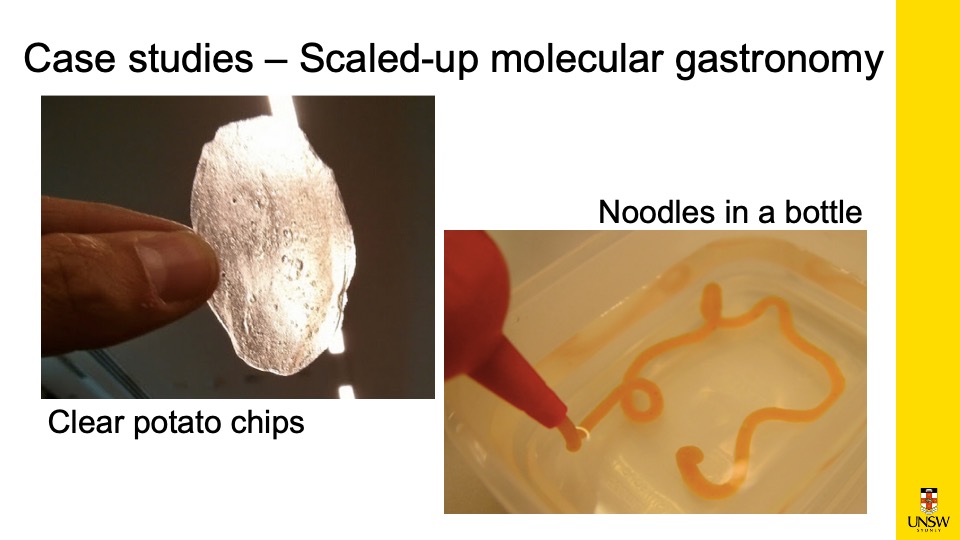

So what did they make? One year a company partner asked if it was possible to create products with the principles of molecular gastronomy that could be mass-produced. One of the standout examples students developed were transparent potato chips, providing the same overall product experience but with radically different appearance that enabled customization by the manufacturer. A senior manager at Pepsico who attended the final presentations was stunned to see the students develop this product as Pepsi had previously pursued the same goal but concluded it was not possible. Another cool idea was noodles in a bottle that exploited a food polymer that gels at high temperatures. The product can be prepared, flavored, and stored in a squeeze bottle then dispensed into hot water or broth to create as much noodle as you need!

Another year our theme was expanding access to products. One student focused on developing a physical sunscreen for non-white skin, as most pigment-based products using titanium dioxide or zinc oxide cause darker skin to look ashy or unattractive. The product was then evaluated for performance and objective change in color. A second product took the analogy of foaming hand soap and asked how the same could be done for toothpaste, reducing the use of abrasives enough to allow its use and reduce the mass in a bottle to enable more efficient transport and use in poorer countries.

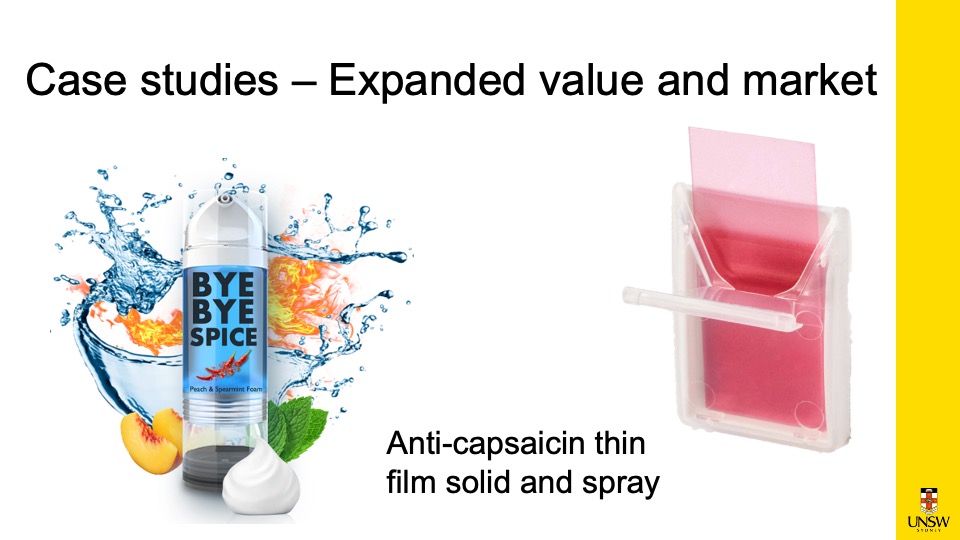

One year we had a rare double development of similar products, both focused on extinguishing the pain of an overly spicy meal. The target market was restaurants who commonly experienced this problem for children who ate the wrong thing. One group developed a foaming preparation of emulsifiers that could remove and encapsulate the capsaicin while a second group made solid forms that could be taken like a breath strip.

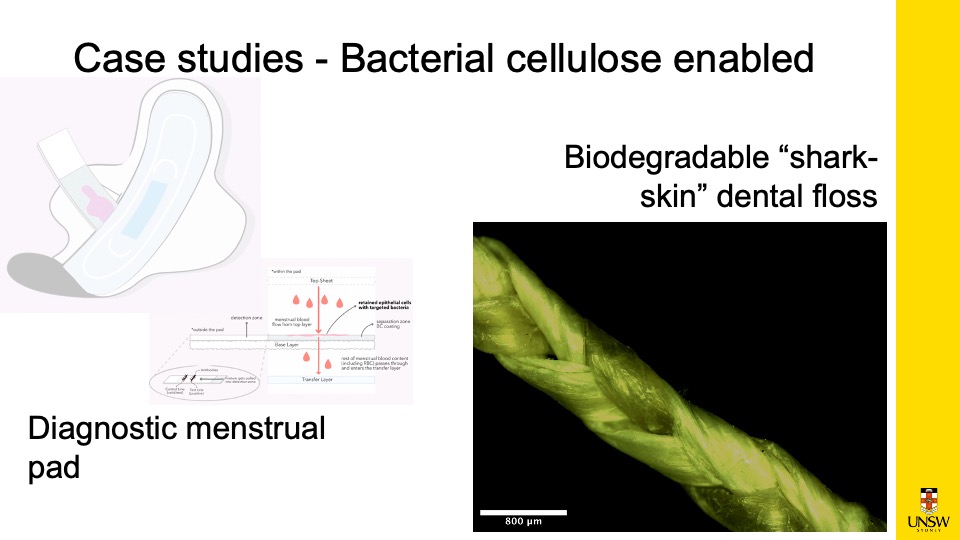

The last couple of years we have developed products that use bacterial nanocellulose to enable product novelty or performance. One of these products was a test strip made to be inserted into menstrual pads to take advantage of sampling proteins bacteria, and antibodies from blood by creating a hierarchically structured porous structure that could be analyzed later as a diagnostic tool. A second group produced entirely biodegradable dental floss using extruded cellulose dispersions that had nanoscale roughness on their surface to enhance cleaning.

So how did we do? Over the last ten years of teaching the course I have had more than 500 students go through the class, producing more than 100 novel products and going on to work in most of Australia's major companies. The class began as a Food Science course, a one-semester class that produced prototype products after only 12 weeks of work. When we created the Chemical Product Engineering stream I morphed the class into a two-semester Honours Thesis form where 10 of the 20 weeks are spent on idea development, refinement, and feasibility testing while the second half focuses on making, testing, and optimizing an actual prototype. Creating the new class required presenting the structure to the Faculty for approval and I was asked how I was so sure students could develop a working prototype in only 20 weeks. By that point I had six years of experience of students doing this in only 12 weeks, with no failures, so it was easy to support the idea.

How do we benchmark against the relevance of the students and their ideas in the marketplace and our targeted industries? Our students have gone on to win prizes in AIFST product development competition. They have founded start-up companies through UNSW Founders program and beyond. Partners like the venture capital firm IndieBio in San Francisco last year offered to work on a startup for the winning menstrual pad diagnostic product. Our partner JoyHarvest hired an intern at the final poster session this year to explore the ice cream that didn't lose its structure when melting.

I'm really pleased to say we met our original goal of providing students with experience in development and design, that not only makes for an illuminating and interesting job interview, but actually forms the basis for hiring by setting them apart from their peers. We consistently hear back from graduates that their product project dominated their discussion with interviewers, leading to hiring of the students as product developers for companies like Woolworths, Unilever, Selley's, etc.

Some representative positive feedback we commonly receive is that students find the class one of the only times they are able to use their creativity so extensively in their engineering study. One mentioned that while they are skilled with mathematical treatment of problems, they feel like that is often the end rather than the means of many of their courses and this project allowed them to creatively define the problems to be solved and more fully engage them in the mathematical modeling of the concept needed. Students more accustomed to well-defined problem assignment can struggle initially but often report the group structure and discussions provide the support needed to adapt.

Thank you again for allowing me the time to talk about this today. I hope I illustrated why I think that we can teach chemical engineers product design, that they use their engineering skills to do product design AND create more rapidly scaled products, and that doing so is good for the field and Australia. I'd like to thank the organizers again as well as my colleagues Richard Li, Stuart Prescott, Pierre Le Clech, Vicki Chen, and Guangzhao Mao for their collaboration and inspiration on this work. I'd also really like to thank the students who have never failed to embrace new concepts, deliver innovations, and impress us and our industry colleagues.