Soft Matter Hacker Talks |

|

|---|

Home - Research - Publications - Blog - Talks - About

Twitter | Instagram | LinkedIn | Google Scholar | Scopus | ResearchGate | UNSW | YouTube

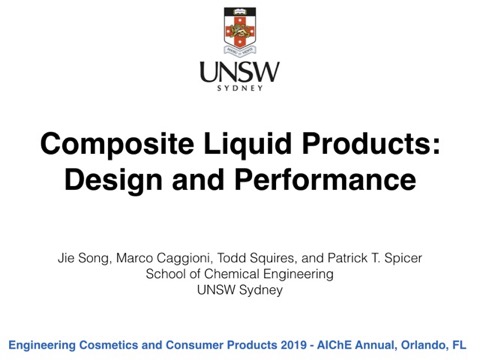

I called this talk Liquid Composites, as I want to focus on some weak parallels I see between the construction of advanced solid composite materials and the design and production of consumer products with novel and valuable properties. I also wish to show how our approach to design and troubleshooting commercial complex fluids has evolved and speculate a bit on where we are headed. The work reflects ideas and effort from my co-authors Todd Squires, Marco Caggioni, and Jie Song.

Here is the definition of composites, and my key example is the inclusion of carbon fibers in a resin material in order to obtain enhanced toughness and crack resistance with minimal additive. Such an effort requires designing the individual material properties and their interactions. The approach to these materials is a recognition of the need to consider not just bulk material properties but also multiple length scales of microstructure. In the field of consumer products, consumer needs have evolved to reflect desire for additional benefits, and our microstructures are built around the agent of the coveted benefits.

Shampoo is a classic example, evolving from a cleaner designed to remove built-up biological and environmental oils to something that must clean, then soften (by adding new oils), kill dandruff fungus, preserve color, and deliver activated carbon! Aesthetics are a part of this too, as in the case of pigments added to conditioning shampoos to make them more alluring and (probably) hide the emulsified oils used to soften hair. They work by having optical properties and shapes that collectively cause a Fresnel interference effect that gives a product depth and makes it resemble a pearl: pearlescence. Here the concept is one of altering the appearance of a fluid seen as largely homogeneous. Many of you in the audience look at this structure and see something other than beauty: they see a colloidal gel.

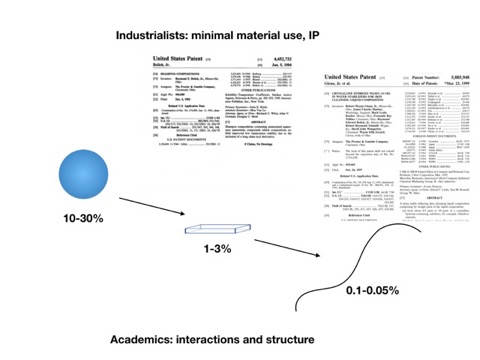

It was recognized that colloidal additives like these pigments provide rheological modification, and the amount added was always a cost concern. Material shape aids in efficiency, and patents through the years reflect a desire for increased performance as well as efficiency. Increasing colloid aspect ratio drives down the amount needed for rheological benefit by orders of magnitude, with a similar reduction in cost, similar to our solid composite analogues.

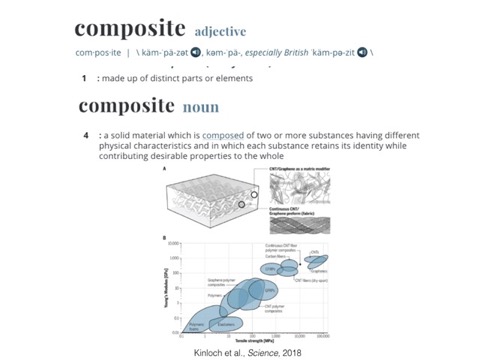

So how are these materials composites? Rheology is a sensitive probe of the response of consumer products to stress. Here we see the fluid microstructure as a single system as well as the two key components: our friend the pigment particle and a background fluid of wormlike surfactant micelles made by adding salt to an aqueous anionic surfactant. We see this is a surprisingly ideal composite liquid with all of the desirable product attributes. The worms are shear-thinning feel, so the product is rich in the bottle, with a viscosity identical to honey, but sufficiently thinning that it spreads easily and spares your hair follicles in a way honey can’t. The colloidal gel is perfectly minimal, with a yield stress that suspends oil drops and recovering quickly from multiple pours.The full material shows how nicely they combine: it’s rare to see such an additive system because of the many possible interactions between complex fluid ingredients. This is a liquid composite with optimized properties.

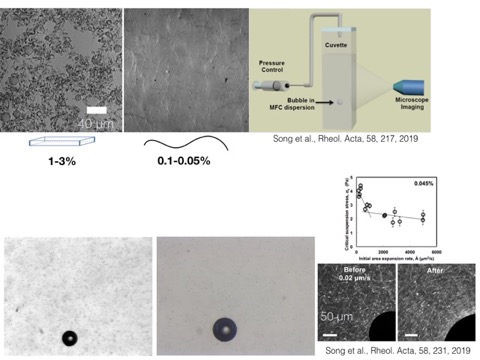

Continuing the advance of such design innovations requires us to think about not just bulk properties but also effects of other length scales. Here we use a microrheology technique, with a single microbubble as our probe, whose size (and the stress it exerts on the fluid) we can adjust by changing the pressure over the system. This means we can measure very small yield stresses but we can also resolve even more subtle responses of the system. An example is the local restructuring of the material to resist stress as the open structure compacts and becomes 4-10X stronger rather than breaking. This mitigates sudden shocks, such as might be experienced during transport on bumpy roads. The local reinforcement is an unintended consequence of the open structure of the network, stemming originally from a desire to spend less on structurants. Greed is good!

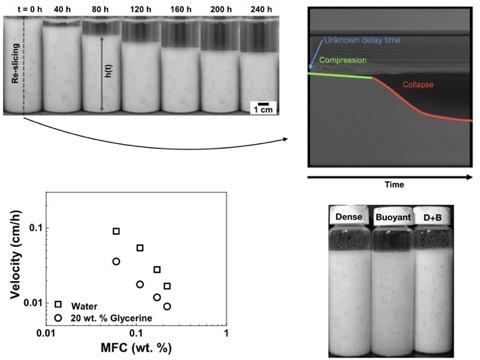

Products have many demands, and I’ve talked about aesthetics of appearance as well as feel and suspension of actives. Another key trait is shelf-life. As good as colloidal networks are at suspending materials, they can undergo an insidious failure mechanism called delayed collapse. In such cases, the load of suspended particles ages, coarsens by diffusion, and then begins to fall. The rate of failure is key to product lifetime, but the random driving force of the delay makes prediction hard. Companies can wind up putting product on the shelf for months to be sure. A key insight came from a physical model of the phenomenon that shows that once collapse begins it has two stages: linear compaction limited by the hydraulic back-flow of continuous phase, then an exponential decay to a final gel height. We found that these cellulose fibers, nano-thin but micro-long, are too long to diffuse so have no delay. This makes prediction of collapse time easy, allowing us to design the rate of collapse using formulation variables like background fluid viscosity. As consumers demand more features be packed into our structures, we must innovate the core technologies as well as their supporting materials.

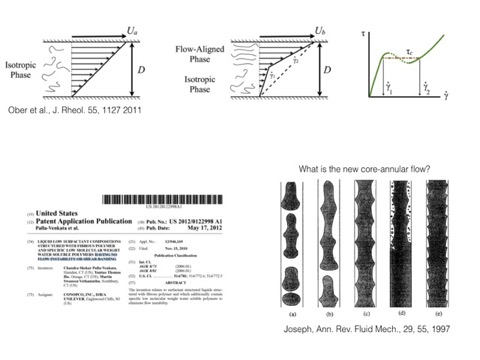

So where are we headed? I think another fascinating phenomenon will play an increasing role in future products, and may very well already affect existing ones as in my previous examples. Shear banding occurs when complex fluids have a discontinuous velocity transition within a flow field. Early work on this behavior focused on it as a nuisance, making measurements inaccurate and affecting process equipment design and reliability. I did a search of the patent literature, and the main references are negative: patents for “non-shear-banding fluids” leave no room for tolerance of these gentle phenomena. However, just as we came to see our superficial pigment as a strong product backbone, I predict a similar renaissance for the shear bands. An analogy is the core-annular flow harnessed to aid pipeline flow, inhomogeneous flow is at the center of many key products.

Recognition of complex fluids has matured, and I think the field will move to approach their design in a way reminiscent of composite materials. Commercially we see a common cycle is the evolution of a component from nuisance to enabler. Sophisticated product design will always demand greater insights. I think about this stuff a lot now, and it is an active area of our new Chemical Product Engineering stream at UNSW. Come try it with us!